I mentioned to a weaving friend that I was working on overshot today… and they suggested *gauze*. And we laughed heartily… And then I did it. Lol. Who’s laughing now?

I am (as ever!) surprised by how it came off the loom. It is suitable as a light-duty potholder, and would make a great coaster. You could even sew it onto something (around 3 edges) as a patch pocket! It gently bulges. Another amazing fabric, courtesy our ancestors in string technology.

Ok, so what is gauze, you ask? Wikipedia is pretty solid here:

In technical terms “gauze” is a weave structure in which the weft yarns are arranged in pairs and are crossed before and after each warp yarn keeping the weft firmly in place. This weave structure is used to add stability to fabric, which is important when using fine yarns loosely spaced. However, this weave structure can be used with any weight of yarn, and can be seen in some rustic textiles made from coarse hand-spun plant fiber yarns.

— Excerpt from Wikipedia: “Gauze” (CC-By-SA)

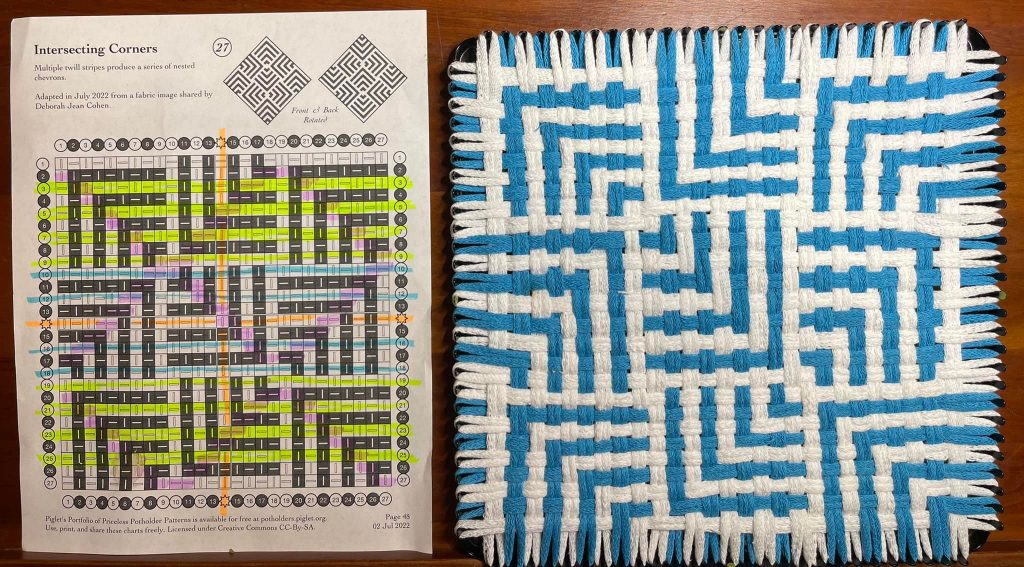

Because of the crossings, I knew my warp threads would tighten up significantly, and also required more space between them, so I decided to use half as many weft loops, on alternating pegs. The last skipped row looked like it would bind off too loosely, to my eye, so I added another weft row on the last row. The result would vary depending how many weft loops were used.

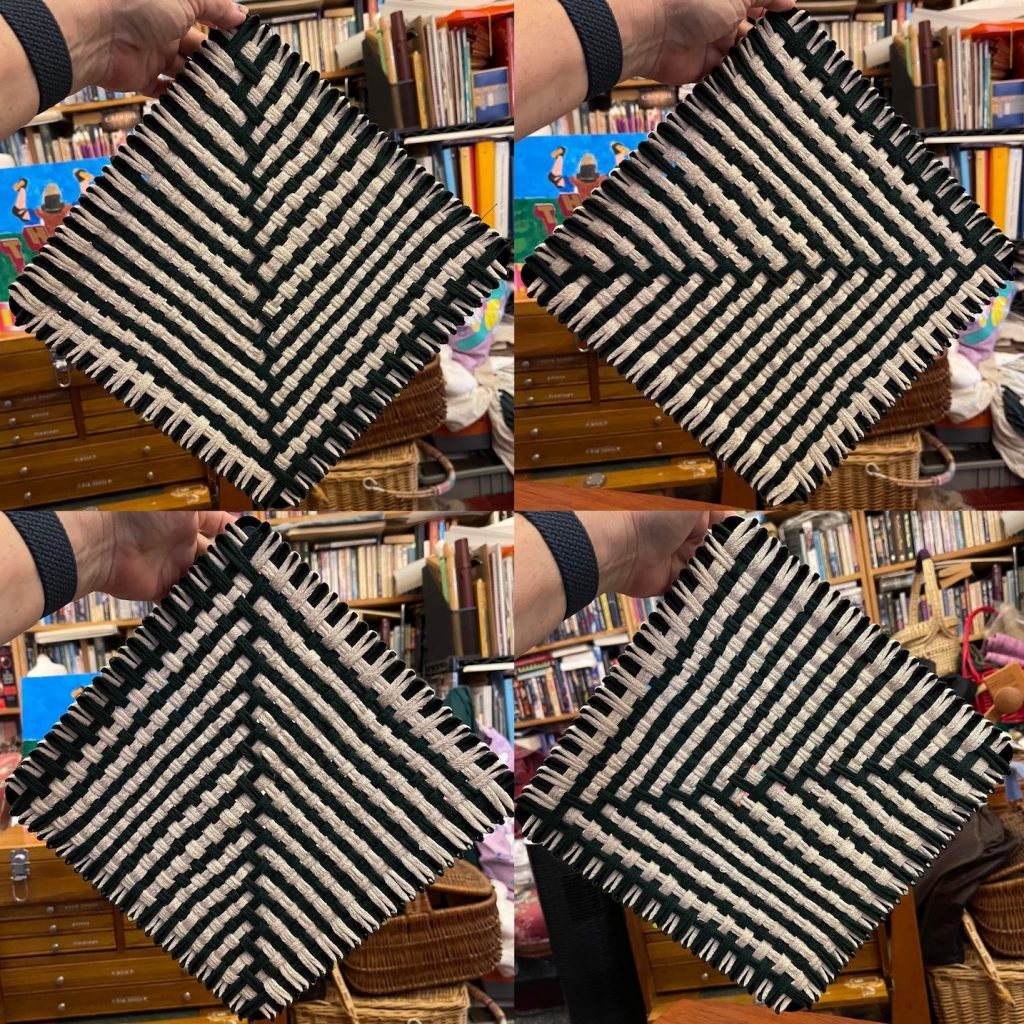

Hopefully the photos give you an idea of how to work the twists. Because we are using potholder looms, with closed loops, we could experiment with putting all the twists in the same direction, introducing a skew in the final fabric that might be interesting. (Also, having done these twists makes me want to try sprang as a technique, lol.)

Postscript, February 2024: I added these notes for someone who was confused about how to weave this structure. — Matthew

The whole piece is worked split-loop, treating the two arms of each warp loop as a pair.

On your starting row, weave over/under across, going over one arm of each warp loop and under the other.

On the next row, for each warp loop, twist it so the arm that was “under” the last time comes up and over its mate, and then back down again so that it can be “under” again but on the other side when the next weft goes through.

The result is that each warp loop is twisted back and forth on alternating rows, with the same arm always being “under” but hopping over its mate to switch from being under on the left to being under on the right and back again.

The result is a light, breathable fabric — the loops are tensioned into place, so they don’t gap or flop around, but there are lots of little spaces built into it.